-

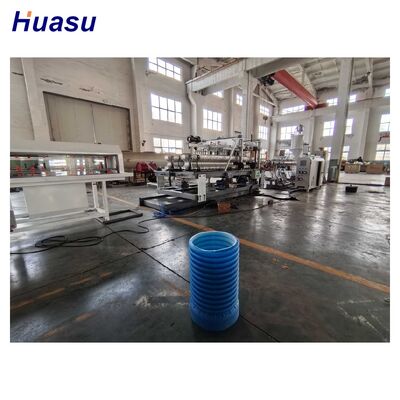

Linia do wytłaczania rur z podwójną ścianką

-

Linia do wytłaczania rur z pojedynczej ściany

-

Linia do wytłaczania rur HDPE

-

Linia do wytłaczania rur DWC

-

Linia do wytłaczania rur PP

-

Linia do wytłaczania rur PVC

-

Linia do wytłaczania rur spiralnych

-

Linia do wytłaczania rur ochronnych kabli

-

Linia do wytłaczania rur z tworzyw sztucznych

Water Supply Corrugated Plastic Pipe Production Line Offering Production of Flexible Pipes for Water Transport Solutions

Skontaktuj się ze mną o darmowe próbki i kupony.

WhatsApp:0086 18588475571

WeChat: 0086 18588475571

Skype: sales10@aixton.com

Jeśli masz jakiekolwiek obawy, oferujemy 24-godzinną pomoc online.

x| Main Motor | Siemens Beide | Pipe diameter range | 32mm - 1600mm |

|---|---|---|---|

| Processing Type | Extruding Machine | Applicable Industries | Manufacturing Plant |

| Plastic Type | PVC/PE/MPP/PA/HDPE | Cooling Method | Air Cooling And Water Cooling |

| Raw Material | PVC/PE/MPP/PA/HDPE Granules And Pellets | Automation | Automatic |

| Podkreślić | HDPE corrugated pipe production line,flexible water transport pipe machine,plastic pipe extrusion line with warranty |

||

Product Description:

The corrugated pipe production line stands as the third generation of cutting-edge machinery developed by Shandong HUASU. This newest model features significant improvements in both output and production speed, achieving an increase between 20% and 40% compared to earlier versions.

Equipped with advanced online belling technology, the system ensures that the produced corrugated pipes possess outstanding performance characteristics. This innovative enhancement greatly improves the quality and uniformity of the final products.

Additionally, the entire manufacturing workflow is managed by a Siemens PLC control system. This high-tech platform optimizes operational efficiency and guarantees dependable performance across the whole production line.

Features:

Introducing a newly engineered closed molding machine, equipped with a specialized high-efficiency cooling system designed specifically for aluminum modules. This innovation ensures optimal temperature control during the molding process, enhancing overall product quality.

Our high-speed, high-output single-screw extrusion machine is paired with a professional-grade corrugated pipe extrusion mold. This combination guarantees superior performance and efficiency in production, meeting the demands of advanced manufacturing.

The interchangeable modules are crafted from premium LY12 alloy aviation aluminum, containing 5% copper. This composition provides exceptional strength and excellent resistance to corrosion, making the components durable and reliable in various environments.

Utilizing a precision pressure casting process, the products resist deformation and effectively eliminate light pores. This meticulous approach improves the integrity and aesthetic quality of the final items.

We offer customizable waveform solutions tailored to accommodate a wide range of project requirements. This flexibility allows clients to optimize their designs according to specific operational needs.

Additionally, the system includes a computer-controlled automatic DWC cutter that ensures precise positioning and stable operation, contributing to enhanced accuracy and productivity during manufacturing.

Technical Parameters:

Introducing a newly designed closed molding machine equipped with a specialized high-efficiency cooling system specifically developed for aluminum modules. This advanced cooling technology ensures optimal temperature control during the molding process, enhancing product quality and durability.

The system also includes a high-speed, high-output single-screw extrusion machine that comes with a professional-grade corrugated pipe extrusion mold. This configuration allows for efficient production while maintaining precision and consistency in the manufactured pipes.

Our interchangeable modules are crafted from premium LY12 alloy aviation aluminum, containing 5% copper, which significantly improves both strength and resistance to corrosion. This choice of material guarantees longevity and reliable performance in various applications.

The use of a precise pressure casting process effectively prevents deformation and eliminates light pores, ensuring the structural integrity and aesthetic quality of the components. This meticulous manufacturing step contributes to the overall robustness of the final products.

To accommodate diverse project requirements, customizable waveform solutions are available. These tailored options provide flexibility and adaptability, allowing clients to select configurations best suited to their specific needs.

Furthermore, a computer-controlled automatic chipless cutting machine has been incorporated, offering precise positioning and stable operation. This advanced cutting technology enhances efficiency while reducing material waste, making the production process more economical and environmentally friendly.

Applications:

This plastic pipe manufacturing machine is designed to produce high-quality pipes that meet a variety of needs.

It is ideal for water supply systems, providing reliable and safe transportation of water. These pipes ensure that water reaches its destination efficiently and without contamination.

Additionally, the machine produces pipes suitable for drainage systems, facilitating effective management of wastewater. This helps maintain hygiene and prevents environmental pollution.

Moreover, the pipes can be used as electrical cable conduits, offering protection and organization for wiring installations. This enhances safety and simplifies maintenance tasks.

All pipes produced by this machine adhere to strict industry standards, guaranteeing outstanding durability and performance even in the most demanding conditions.